Introduction

This was the fifth of our discovery sessions around the 10 ‘how might we’ questions that make up our current exploration pipeline.

Working out loud is one of our Lab guiding principles and we are really keen to share both our colleagues work and their ideas. We are sharing the high-level themes which emerge from each session, rather than waiting for them to be worked up into something more substantial. Following the sessions, the next steps will be for Innovation and Insight is to work up some solid test plans based on what we learned and we will, of course, be sharing more about those in due course.

Workshop Summary

The output from previous service design work formed the starting point.

Moving to a truly proactive and automated service model requires a significant amount of exploration.

The problem is, we can't always get our stock to the places it needs to be when we need it to be there. Holding stock can be costly, but our suppliers aren't always able to deliver in the flexible way we would like them to, so we often have no other option.

The current logistics process isn't flexible enough and needs to be reimagined.

Key questions to be explored include:

- Is holding stock actually costly? How costly?

- How can new technology enable more efficient logistics?

- Can we develop a different type of relationship with our suppliers?

- Can we procure things in different ways?

During the workshop, we provided a set of ‘design fictions’ for colleagues to discuss. Design Fiction is a design practice which offers a way of exploring possible futures by creating speculative, and often provocative scenarios narrated through designed artefacts, which in this case were a set of posters.

The point of the exercise wasn’t necessarily to identify how to move towards these particular futures, but rather use them as a way of generating some interesting and critical conversation around the problem.

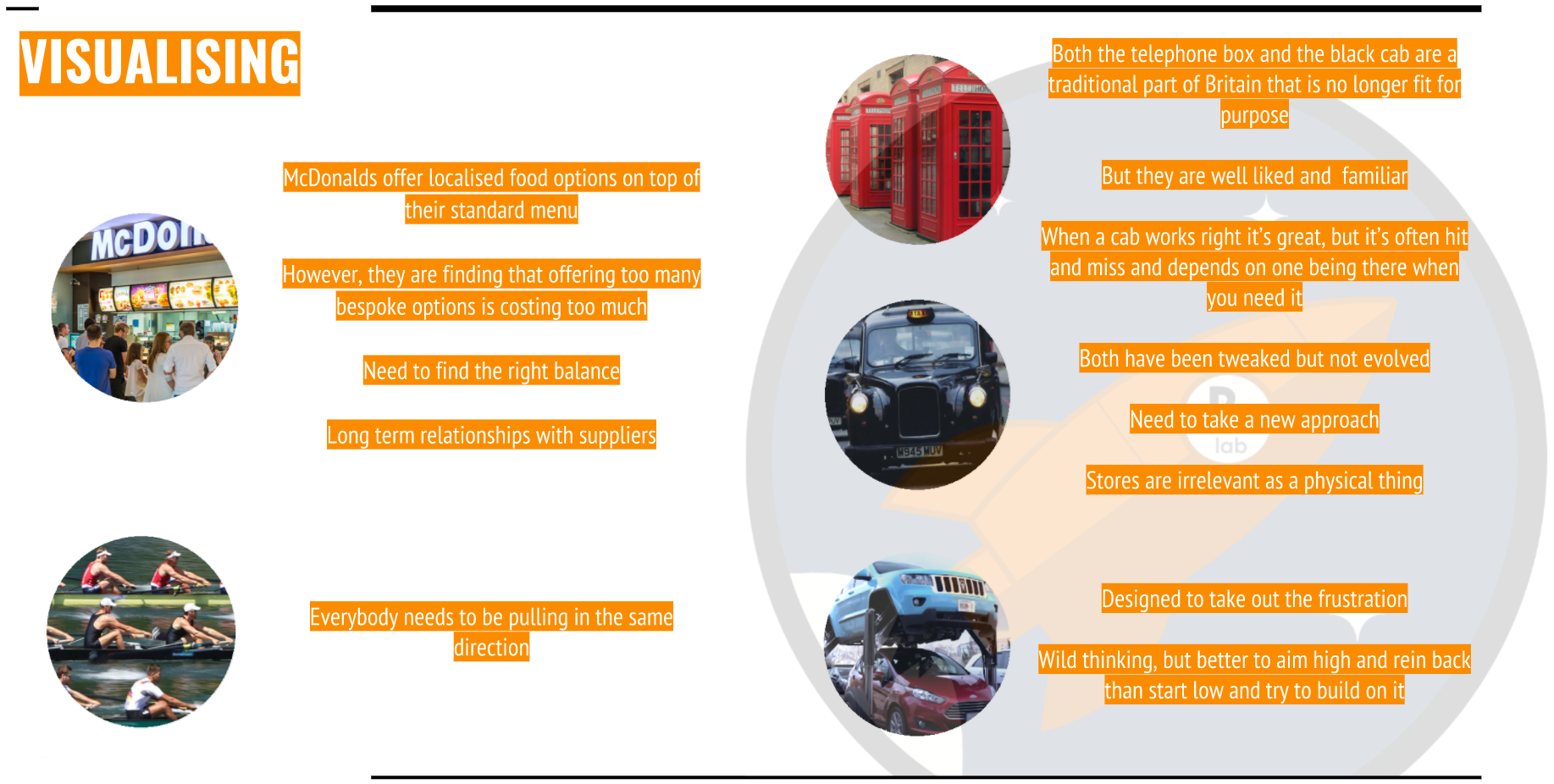

Colleagues were also asked to choose a picture from a random selection of images in order to help us all visualise the important factors at play. With both activities we wanted to create some left brain / right brain inspirational pairings which could take us out of our current sphere of reference and help us start to think analogously about a problem.

During the conversation that followed, some key fundamental principles emerged and colleagues were keen for us to test ways to bring each principle to life:

Colleagues came up with a range of ideas and questions which we boiled down into four high-level themes:

1. RIGHT PART, RIGHT PLACE, RIGHT TIME:

This means a seamless journey incorporating the right diagnostic tools that can identify and order the correct parts. Flexibility around stock management means we can identify the most efficient way to get parts to an engineer, whether this be through deploying ‘drop boxes’ where appropriate or delivering items directly to an engineers van. We will always be as prepared as we possibly can to get it right first time.

2. DATA DRIVEN NEEDS, NOT WANTS:

This means using data to ensure supply is meeting demand and we respond to both our customers' and Bromford's expectations of service. We know what is in our homes which helps us to make better decisions. We will use market data to ensure we remain competitive and will outsource if we recognise someone can provide part of the service better than we can without compromising our high-quality standards.

3. VARIETY IS THE SPICE OF LIFE:

This means that whilst we want to be efficient, standardisation may not necessarily be the best fit. Variety may allow us to reduce waste costs in certain areas and mitigate risk. Whatever we do, we will keep it as simple as possible and strip out unnecessary complexity.

4. WHAT DO WE MEAN BY A SERVICE DELIVERY CENTRE:

This means understanding the consequences of changing the usage or the number of Stock Distribution Centres. What is the wider SDC service offer over and above being a place to store things?

Some of the 'wild ideas' included:

- What if we gave each locality a 3D printer?

- What if we used drones and driverless vans to move items around?

- What if we used drop boxes to keep items safe?

We will be working with colleagues in the coming weeks to look at developing some tests. A key priority will be learning from colleagues and partners who are already working in some of these ways, learning more about the wider services that SDCs offer, exploring the expectations of our customers by continuing our work on developing a set of personas and understanding the impact that geography has on finding the right solutions.

Watch this space.

---